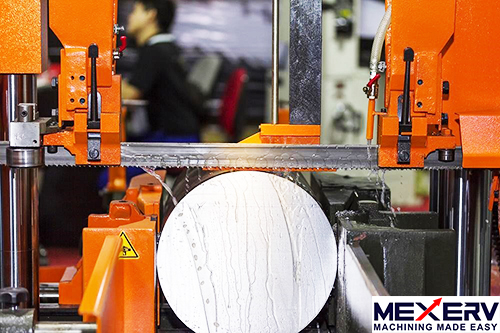

Bandsaw Cutting

In band saw cutting, as the name suggests, the saw is formed as a band and is made to loop in a single direction in a cycle with the help of pulley wheels. Due to this, a continuous cut can be made. An important point to note here is that the blade must be thin enough to bend around the pulley wheels. Contour cuts can also be made and the minimum curvature of the cut will depend on the blade’s cross-section.

In some machines the table angle can be adjusted, thereby producing tapered parts or parts with sides which are angles. For the purpose of lubrication and cooling, certain cutting fluids may be used.

Typical Applications

- Stock cutting

- Profile cutting

Design Guidelines

- Contour cuts can also be made and the minimum curvature of the cut will depend on the blade’s cross-section.

- Convex radii less than 1.5 mm can be achieved in a single pass.

- Close tolerances can be achieved by using automated band saws or a skilled operator with a magnifying glass.

- The optimal range of material hardness for sawing is between 170 and 260 HB, but steels up to 390 HB and some particular steels up to 440 HB can be sawed with slower cutting rates.

- Convex radii less than 1.5 mm can be achieved in a single pass.